A well-built carbon frame dramatically reduces weight compared to metallic materials, while maintaining the strength and stiffness that high performance bicycles and their riders demand. This is where Trek’s pioneered and patented OCLV Carbon—an acronym for Optimum Compaction Low Void—process comes in. OCLV Carbon frames begin with the best material available. Trek has spent countless development hours perfecting the construction of a variety of weights and types of carbon (cloth, unidirectional, etc.). The OCLV process is best explained when broken down into two parts:

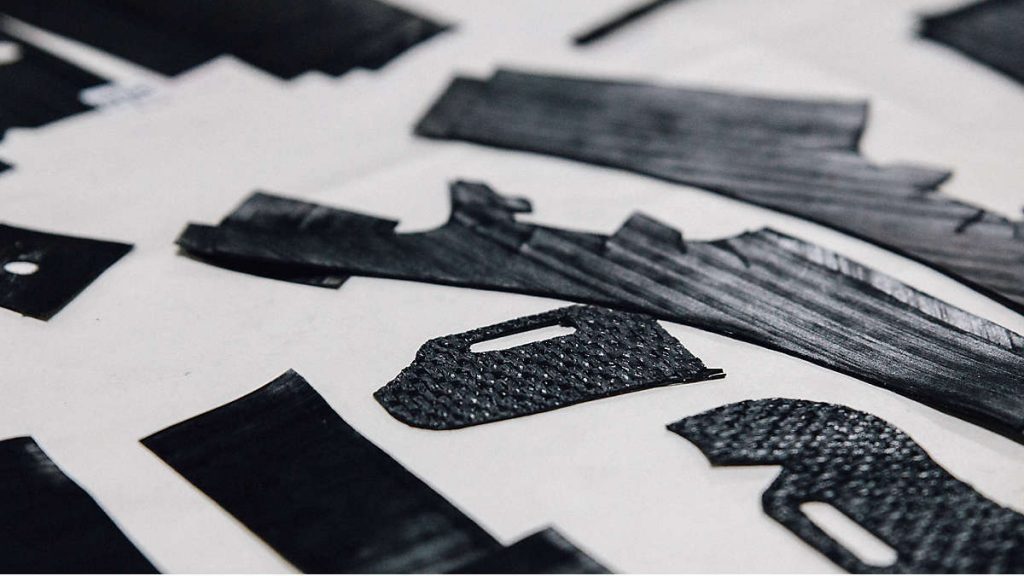

Optimum Compaction: Carbon is layered into a series of plies compacted to the ideal fiber-resin ratio. The process starts with cutting carbon fiber from large sheets to a specific shape which is then placed into a mold. A combination of heat and pressure then compresses the sheets of carbon into a carbon lug. This combination of heat and pressure is OCLV’s most essential and closely guarded equation.

Optimum Compaction: Carbon is layered into a series of plies compacted to the ideal fiber-resin ratio. The process starts with cutting carbon fiber from large sheets to a specific shape which is then placed into a mold. A combination of heat and pressure then compresses the sheets of carbon into a carbon lug. This combination of heat and pressure is OCLV’s most essential and closely guarded equation.

Low Void: Voids are the spaces that exist between the layers of carbon fiber that comprise a component or frame. Minimizing these voids is the primary goal of quality carbon engineering, as more voids translates to reduced strength and durability of the composite material. OCLV Carbon exceeds aerospace standards regarding the number of voids in its material.